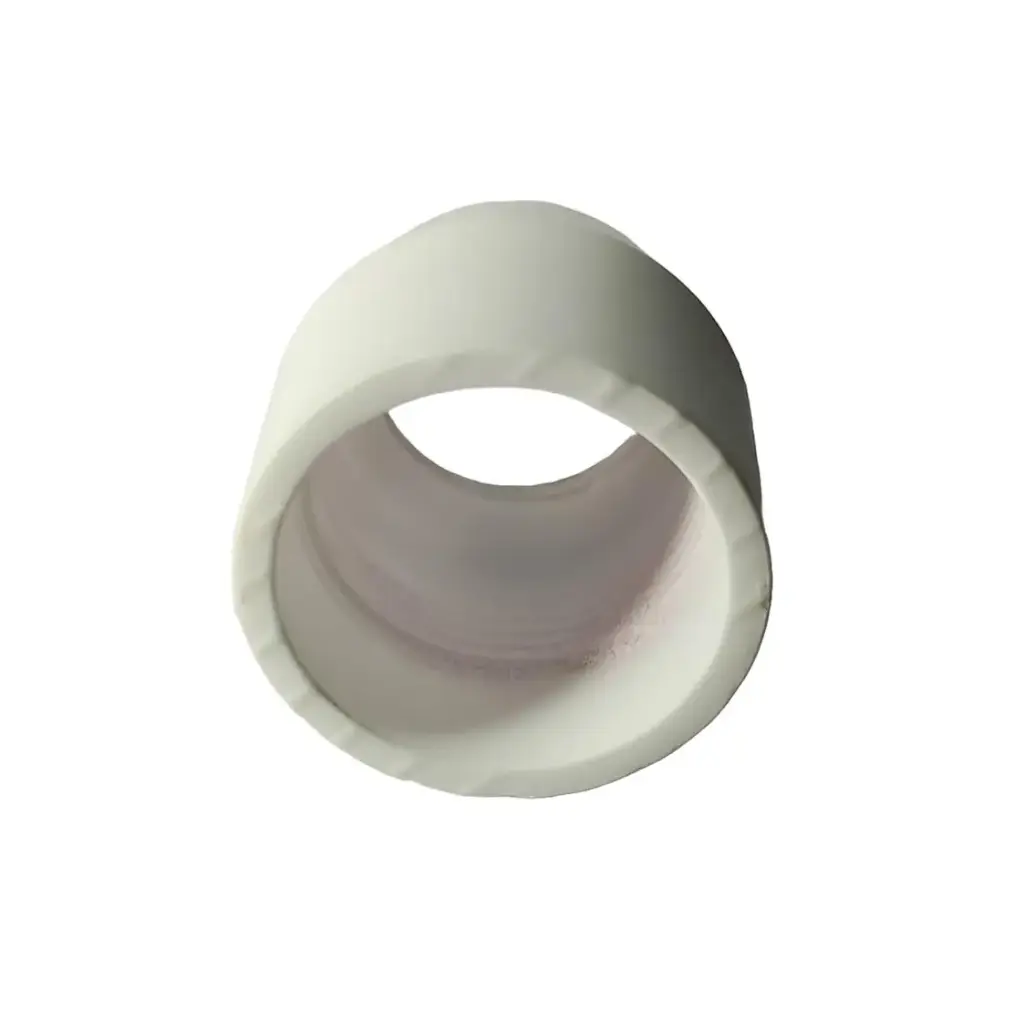

WELDING CERAMIC NOZZLE P-80

The Welding Ceramic Nozzle P-80 (often called a ceramic shield cup or shroud) is a consumable part for the P-80 plasma cutting torch, commonly used in air plasma cutters for metal fabrication, automotive repair, and general workshop cutting. Made from high-temperature alumina ceramic (aluminum oxide), it protects the electrode and tip from molten metal splatter, arcs, and debris while maintaining stable gas flow for clean, precise cuts. The "P-80" designation refers to the torch model (a generic/Chinese equivalent to Panasonic's SG-55 or similar), rated for 80–100A applications. This nozzle is not for MIG/TIG welding gas nozzles (those are separate ceramic types)—it's specifically for plasma arc cutting.

These are affordable, replaceable parts (last 10–50 hours depending on use) and often sold in kits with electrodes and tips. If you're experiencing uneven cuts or excessive wear, the ceramic nozzle is a common culprit. Compatible with brands like RIVERWELD, North Welding, and generic P-80 torches on plasma machines (e.g., CUT-80, LGK-100IGBT).

Key Specifications (Standard for P-80 Ceramic Nozzle / Shield Cup)

| Feature | Details |

| Material | Alumina Ceramic (Al2O3, 99% purity for heat resistance) |

| Dimensions | Outer: D20–25mm x H28–30mm; Thread: M26 x 1.5 (standard P-80 fit) |

| Inner Diameter | 15–18mm (fits 1.1–1.5mm tips) |

| Amperage Rating | 80–100A (optimal at 80A for mild steel) |

| Max Temperature | Up to 1,800°C (3,272°F) – withstands plasma arc heat |

| Cutting Capacity | Up to 40mm clean cut (mild steel at 100A) |

| Thread Type | M26 x 1.5 (universal for P-80 torches) |

| Pack Size | Sold singly or in 5–10 packs; kits with 25+ parts |

| Weight | 10–20g per nozzle |